Featured Article

Discover the enhanced power and innovative features of HTRI SmartPM™ 6.0

January 12, 2026

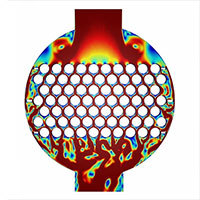

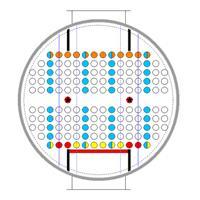

HTRI's innovative digital transformation (DX) software, SmartPM, continues to revolutionize performance monitoring and prediction of many...

Read ArticleArticles

Discover the enhanced power and innovative features of HTRI SmartPM™ 6.0

January 12, 2026

Research Software Technical Support Read More

Discover the enhanced power and innovative features of Xchanger Suite® 9.3

January 15, 2025

Research Software Technical Support Read More

Industry Interest in Electric Heaters Continues to Heat Up

November 06, 2023

Research Technical Support Training Read More